George Mathewson

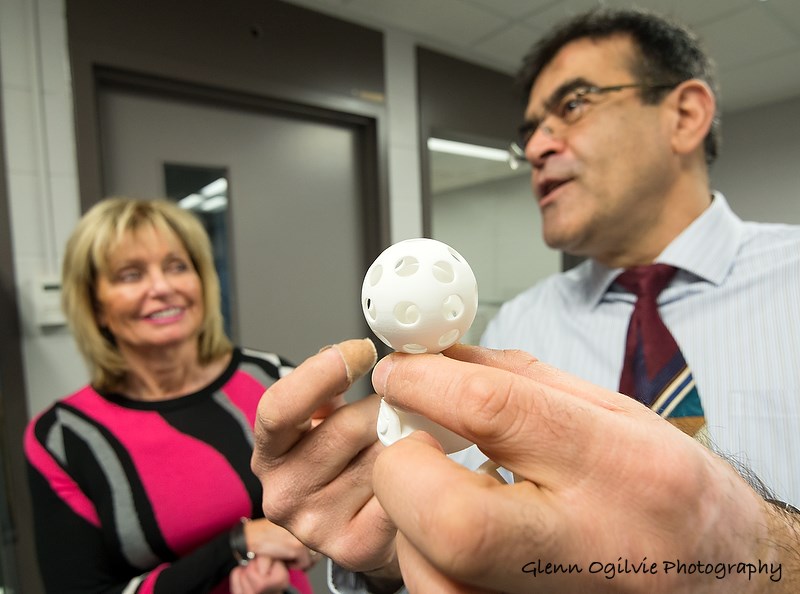

In a shiny new laboratory at the Western Sarnia-Lambton Research Park officials are showing off their latest plaything – a practice golf ball.

Actually, it’s three separate balls that rattle around inside each other – a novelty item that symbolizes how quickly Lambton College has evolved into a centre of research and applied science.

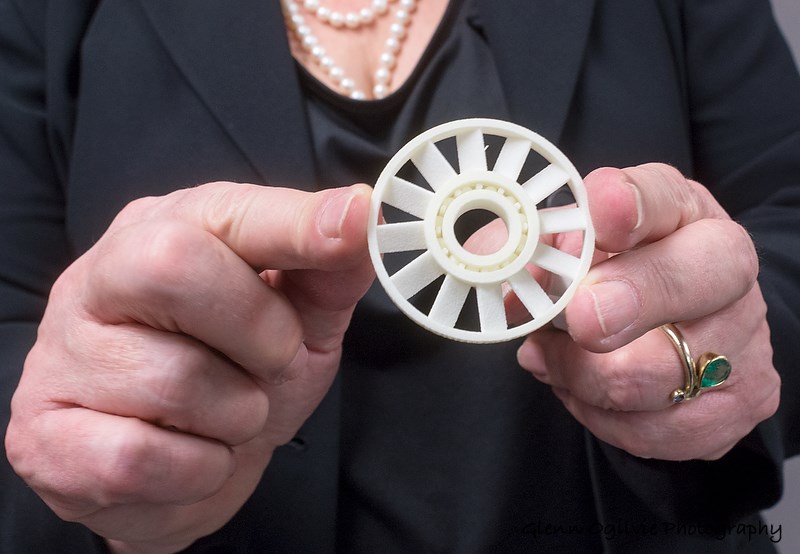

The balls were made with a 3D printer, a process in which thin layers of plastic powder are laid down and fused to create a three-dimensional object.

The new Additive Manufacturing Laboratory on Modeland Road contains a trio of printers, from a $1,500 hobbyist model turning out chess pieces this day to the star of the show – a $250,000 cabinet that uses a laser beam to transform computer designs into … well, just about anything the human mind can envision.

“It really is amazing. To be able to see three balls that were made one inside of each other with no assembly required, that is otherworldly,” said college president Judith Morris.

“And this is where we want to be, frankly. Students here are being given a pretty special opportunity.”

Around the world, 3D printers are producing everything from clothing to food to robots.

A San Diego research company has successfully printed human liver tissue, and engineers at Cornell University printed a working ear. Using cells from the patient’s rib, the ear began growing its own cartilage after three months.

The college’s technology will allow companies to test a concept, produce it at the centre with little waste, and get it to market quickly, said Maike Luiken, director of the Bluewater Technology Access Centre.

The centre does not yet have any industry partners, but it’s close.

Two companies have patent applications in the works for prototype of parts with residential and commercial potential, she said, adding that being more specific could scuttle the patent.

An announcement from a large corporation is expected soon.

The college printers can only make plastic objects. Metal printers are available but expensive and require more lab space.

The new equipment, purchased with federal research grants, means the centre can offer businesses 3D computer aided design and digital scanning as well.

Morris said the technology is so new many in the private sector haven’t yet grasped how 3D printing, also known as additive manufacturing, can help them.

“And so we’re providing that opportunity,” she said. “Their minds start to work, and they’ll come back to us and say, ‘Ah, now I can see how we can use it.”

Tours of the centre are available by calling 519-383-8303, ext. 238, or e-mailing [email protected].